Have you ever wondered why the wires in your car’s tail light are different colors? Understanding the color code for tail light wiring is essential for every car owner. These colors play a crucial role in ensuring your safety on the road, indicating the functions of different wires and making troubleshooting easier. From brake lights to turn signals, each wire color holds a specific meaning. In this article, we will explore the significance of the color code for tail light wiring, helping you navigate the intricate network of wires behind your car’s rear end.

Overview of Tail Light Wiring

Understanding tail light operation

Tail lights are an essential component of any vehicle’s lighting system. They are located at the rear of the vehicle and play a crucial role in increasing visibility and indicating the driver’s intentions to other road users. Tail lights are typically illuminated when the headlights or parking lights are turned on and are activated when the brakes are applied or the turn signal is activated.

Components involved in tail light wiring

The tail light wiring system consists of several components that work together to ensure proper lighting and functionality. These components include the tail light bulbs, wiring harness, connectors, sockets, and switches. Each of these parts has a specific role in the overall operation of the tail lights.

Role of tail light wiring in vehicle safety

Tail light wiring is vital for ensuring the safety of both the driver and other road users. Properly functioning tail lights help drivers to see and be seen, especially in low-light conditions or during inclement weather. By providing rear illumination, tail lights alert other drivers to the presence, size, and position of the vehicle, making it easier to judge distance and avoid accidents.

Importance of Color Coding in Tail Light Wiring

Rationale behind implementing color codes

Color coding in tail light wiring serves as a standardized way to identify and differentiate the various wires within the system. By assigning specific colors to different functions or circuits, it becomes easier for technicians and DIY enthusiasts to understand and troubleshoot the wiring. This uniformity also ensures consistency and reduces the risk of errors during installation or maintenance.

Benefits of well-defined color coding

Well-defined color coding in tail light wiring provides numerous benefits. It allows for quick and accurate identification of wires, simplifies troubleshooting, aids in proper installation, and facilitates future repairs or modifications. It also enhances safety by minimizing the chances of accidentally connecting wires incorrectly, which could lead to short circuits or system failures.

Understanding the complexity of wiring without color codes

Without color coding, tail light wiring can be incredibly complex and confusing. The wiring harness may contain numerous wires of different sizes, gauges, and functions, making it difficult to determine which wire is responsible for a specific task. This lack of uniformity can lead to mistakes during installation or troubleshooting, resulting in wasted time, increased costs, and potential safety risks.

Common Color Code Standards

American color codes for tail light wiring

In the United States, tail light wiring often follows a standard color code. The most common color coding found in American vehicles includes black for ground, brown for taillights, yellow for left turn signal, green for right turn signal, red for brake lights, and white for reverse lights. However, it’s important to note that some variations may exist depending on the vehicle’s make and model.

European color codes for tail light wiring

European vehicles generally adhere to their color code standards for tail light wiring. This often includes brown for taillights, yellow for left turn signal, green for right turn signal, red for brake lights, black for ground, and blue for reverse lights. As with American color codes, it’s important to confirm the specific color coding for a particular vehicle.

Asian color codes for tail light wiring

Asian vehicles, such as those from Japan or South Korea, typically have their own color code standards for tail light wiring. Common colors in Asian vehicles include brown for taillights, yellow for left turn signal, green for right turn signal, red for brake lights, black for ground, and purple for reverse lights. However, it’s crucial to consult vehicle-specific documentation for accurate color code information.

Detailed Breakdown of Color Codes

Deciphering the color code of tail light wiring

Understanding the color code of tail light wiring requires careful observation and reference to vehicle-specific documentation. Each wire’s color corresponds to a specific function or circuit, and deciphering this code allows for accurate troubleshooting, repair, or modification. It’s essential to identify and confirm the color code for each wire before performing any work on the tail light wiring system.

Role of each wire color in the system

Each wire color in tail light wiring has a specific role in the system. For example, black wires are often used for the ground connection, providing a safe pathway for electrical current to flow without interference. Brown wires are commonly associated with taillights, illuminating the rear of the vehicle at nighttime. Yellow and green wires are dedicated to left and right turn signals, respectively, while red wires are responsible for brake lights. White wires often connect to reverse lights, signaling that the vehicle is in reverse gear.

Identification guide for special colored wires

In some cases, tail light wiring may include special-colored wires that serve unique purposes or connect to additional features. These wires can vary depending on the vehicle’s make, model, and optional equipment. It is crucial to consult the vehicle’s wiring diagram or documentation to accurately identify the function associated with special-colored wires.

Universal Color Code for Tail Light Wiring

Common color codes recognized globally

Despite regional variations, there is a push towards recognizing a universal color code for tail light wiring. This allows for better standardization across different vehicle models, reducing confusion and simplifying repairs or modifications. While specific colors may vary slightly, the general principles of black for ground, brown for taillights, yellow for left turn signal, green for right turn signal, red for brake lights, and white for reverse lights are widely accepted.

Steps to identify universal color codes

To identify universal color codes for tail light wiring, it is important to refer to the vehicle’s user manual, wiring diagram, or consult online resources for accurate information. After identifying the preferred universal color code, the existing tail light wiring can be labeled or modified accordingly to match the desired standard. It’s essential to double-check and confirm compatibility with the vehicle’s electrical system before making any changes.

Effects of adhering to universal color codes

Adhering to universal color codes for tail light wiring provides numerous benefits. It ensures compatibility with standardized wiring components and accessories, simplifies troubleshooting and repairs, and reduces the learning curve for technicians or DIY enthusiasts. Additionally, it enables easier communication between individuals working on vehicles, eliminates confusion caused by different color coding standards, and promotes safer and more efficient electrical connections.

Finding Tail Light Wiring Diagrams

Importance of wiring diagram in color code identification

A wiring diagram is an invaluable resource when it comes to identifying color codes in tail light wiring. It provides a visual representation of the wiring system, including the colors and connections of each wire. By referring to a wiring diagram, technicians or DIY enthusiasts can accurately determine the purpose of each wire and ensure correct installation, troubleshooting, or modifications.

Places to find correct tail light wiring diagrams

Finding correct tail light wiring diagrams can be done through various sources. The vehicle’s user manual often includes a section dedicated to electrical systems, including wiring diagrams. Additionally, automotive repair manuals, both in print and digital formats, provide detailed illustrations and explanations of the tail light wiring system. Online forums, manufacturer websites, and automotive-focused websites may also contain wiring diagrams or provide links to trusted resources.

Understanding and reading a tail light wiring diagram

Reading a tail light wiring diagram requires some understanding of electrical symbols and conventions. Each wire is represented by a line on the diagram, and the color of the line corresponds to the color of the wire. The diagram also indicates the connections, switches, and components involved, providing a clear understanding of how the tail light wiring system operates. It’s essential to refer to the diagram’s legend or key to ensure accurate interpretation.

Troubleshooting Tail Light Wiring Issues

Signs of a potential wiring problem

Several signs may signal potential tail light wiring problems. These include dim or flickering tail lights, non-functioning lights despite replacing bulbs, intermittent operation, blown fuses, or dashboard warning lights indicating an electrical issue. Additionally, physical damage to the wiring or connectors, corrosion, loose connections, or melted insulation can also point towards underlying wiring issues.

How to locate issues using color codes

Color codes play a crucial role in troubleshooting tail light wiring problems. By referencing the wiring diagram and utilizing the color-coded wires, technicians or DIY enthusiasts can identify faulty connections, damaged wires, or improper installations. By using a multimeter or continuity tester, the continuity of each wire can be tested to ensure that electrical signals are flowing properly, thereby locating and rectifying any issues.

Solving common tail light wiring problems

Common tail light wiring problems can often be resolved by following a few troubleshooting steps. This may include checking and tightening loose connections, replacing damaged or worn-out wires, repairing or replacing faulty switches or connectors, or ensuring proper grounding. In some cases, it may be necessary to seek professional assistance to diagnose and resolve more complex issues or to perform intricate repairs.

Replacing Tail Light Wiring

When to replace tail light wiring

Tail light wiring should be replaced if it is damaged, extensively corroded, or causing persistent issues despite attempts at repair. Signs that may indicate the need for replacement include frayed or bare wires, melted insulation, severe corrosion, or irreparable damage due to accidents or extreme weather conditions. Regular inspections and maintenance can help identify potential wiring problems early on and prevent more significant issues down the line.

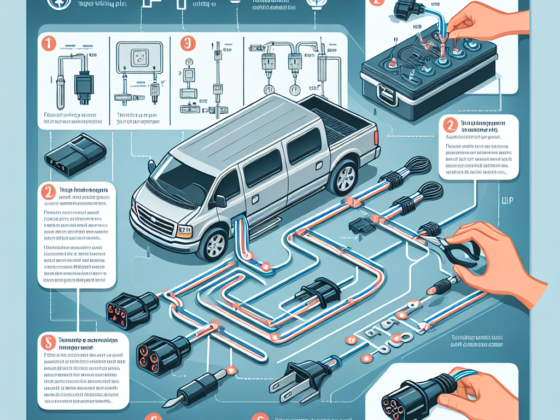

Steps to replace tail light wiring using color codes

When replacing tail light wiring, it is crucial to follow a systematic approach to ensure proper installation. Steps may include disconnecting the battery to prevent electrical shock, removing the damaged wiring and connectors, identifying and labeling the color-coded wires, securing the new wiring and connectors, and testing the system for proper functionality before finalizing the installation. Care should be taken to match the color codes of the new wiring with the original wiring or adhere to universal color codes if desired.

Safety precautions while replacing tail light wiring

Replacing tail light wiring involves working with electrical components and requires proper safety precautions. It is crucial to disconnect the vehicle’s battery before starting any work to prevent electrical shocks or damage to the wiring. Additionally, wearing safety glasses and gloves can protect against sharp edges or potential hazards. Following manufacturer guidelines, using appropriate tools, and exercising caution can help ensure a safe and successful tail light wiring replacement.

Professional Assistance and Tail Light Services

Hiring professionals for tail light wiring jobs

For those who are not experienced or comfortable working with automotive electrical systems, hiring professionals for tail light wiring jobs is highly recommended. Certified technicians or auto electricians have the necessary expertise, tools, and knowledge to accurately diagnose, repair, or replace tail light wiring. Professional assistance ensures the job is done correctly, minimizing the risk of further damage or electrical issues.

Services provided by tail light wiring experts

Tail light wiring experts offer a range of services to address various needs related to tail light wiring. These services encompass tail light wiring repair, replacement, installation of aftermarket lighting accessories, troubleshooting complex electrical issues, and upgrading outdated wiring systems. They often have access to specialized equipment or diagnostic tools, allowing them to efficiently and effectively resolve tail light wiring problems.

Evaluating the quality of tail light wiring services

When seeking tail light wiring services, it is important to evaluate the quality of the service provider. Considerations include their experience and qualifications, whether they use genuine or high-quality replacement parts, their reputation within the automotive community, and any warranties or guarantees offered. Reading reviews, seeking recommendations, and asking for certifications or accreditations can help assess the credibility and expertise of tail light wiring service providers.

Future Trends in Tail Light Wiring

Innovations in tail light wiring color coding

As automotive technology advances, tail light wiring color coding is expected to evolve as well. Innovative solutions may include the use of smart or adaptive lighting systems capable of adjusting the light output based on driving conditions or intended signals. This could require new or modified color coding systems to differentiate between various lighting modes, improve visibility, and ensure compatibility between advanced lighting features and existing wiring standards.

Impact of technology on tail light wiring

Technology is playing an increasingly significant role in tail light wiring. Advancements in LED lighting, connectivity, and automation are influencing how tail light wiring is designed and integrated into vehicles. For example, LED lights consume less power and offer greater reliability, requiring different electrical considerations. Additionally, connectivity features may necessitate additional wiring for communication between the tail lights and other vehicle systems. These technological advancements are shaping the future of tail light wiring.

The place of color coding in future automotive wiring

Color coding is expected to remain a crucial aspect of future automotive wiring, including tail light systems. As vehicle designs become more complex and advanced technologies are integrated, clear and standardized color coding will continue to simplify installation, troubleshooting, and repairs. Additionally, as new lighting technologies emerge, color coding will play an important role in ensuring compatibility and establishing industry-wide standards for wiring systems across different manufacturers and models.