Have you ever experienced frustrating tail light wiring problems in your vehicle? Whether it’s a faulty connection, a short circuit, or a damaged wire, these issues can not only be annoying but also pose a safety hazard on the road. In this article, you will discover simple and effective tips to put an end to those pesky tail light wiring problems. By following a comprehensive stop turn tail light wiring diagram and implementing a few troubleshooting techniques, you will be able to enjoy a safe and hassle-free driving experience. Say goodbye to flickering lights or non-functional signals – it’s time to get your tail lights shining bright again!

Understanding Tail Light Wiring

When it comes to your vehicle’s tail lights, understanding the wiring is crucial. Tail light wiring refers to the electrical connections that power the tail lights of your vehicle. This wiring system allows your tail lights to illuminate, indicating your presence on the road to other drivers.

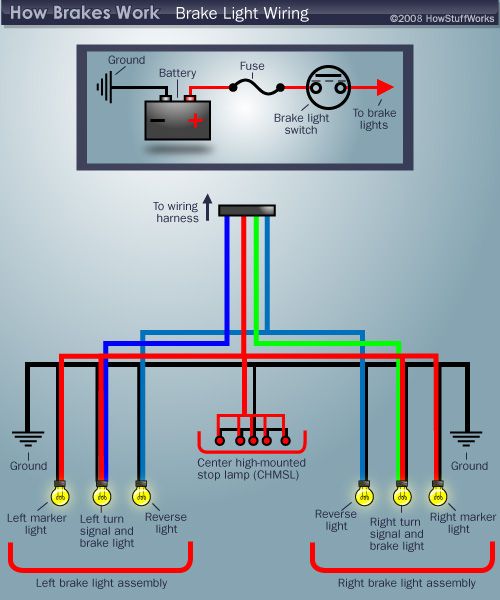

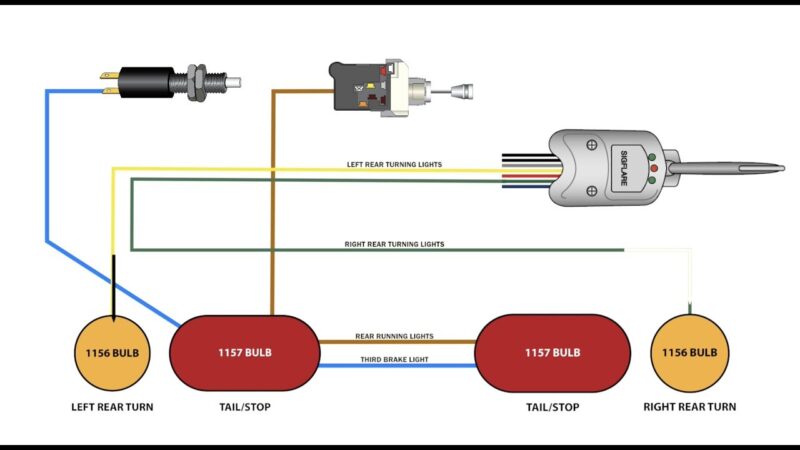

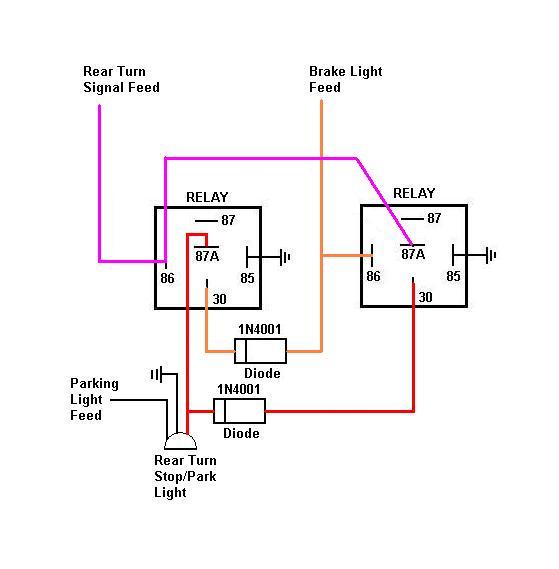

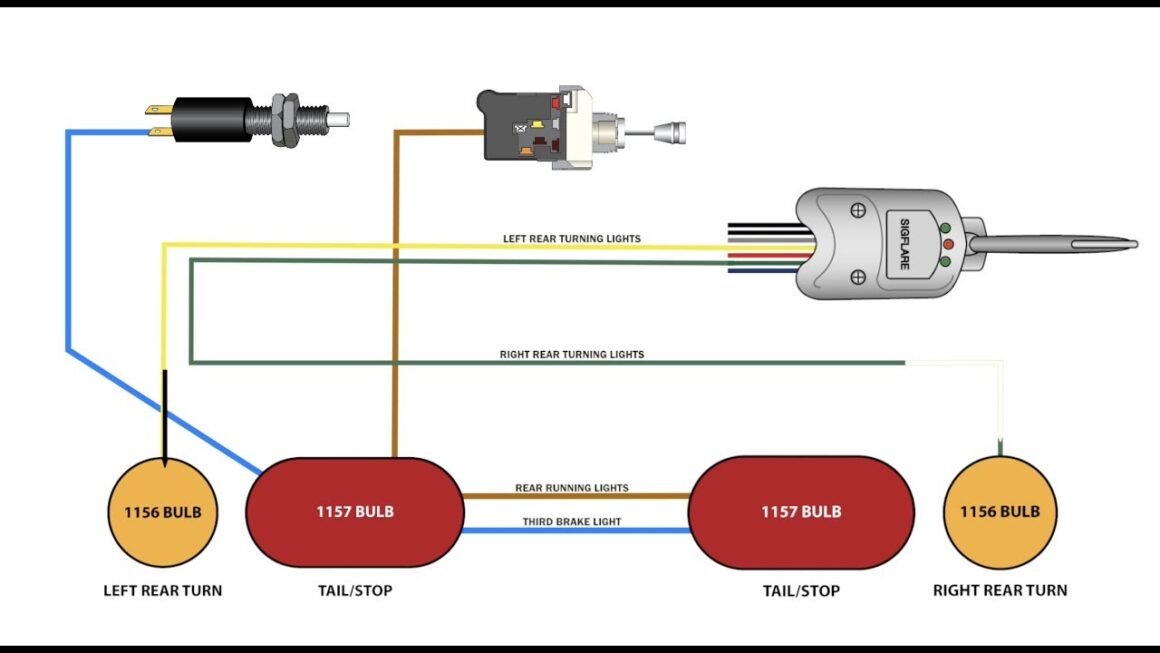

The structure of tail light wiring

Tail light wiring consists of several components that work together to ensure proper functioning of your tail lights. These components include wires, connectors, fuses, and bulbs. The wiring system is designed to deliver electrical power from the vehicle’s battery to the tail lights, enabling them to light up when needed.

Common problems with tail light wiring

Tail light wiring can experience various issues over time. Some common problems include loose connections, damaged wires, blown fuses, and faulty bulbs. These issues can result in malfunctioning or non-functional tail lights, which can compromise your safety on the road.

Why tail light wiring issues occur

Tail light wiring issues can occur due to a variety of reasons. One common cause is wear and tear over time, as the wires and connectors may become corroded or damaged. Additionally, accidents or mishaps can also lead to wiring problems. Understanding why these issues occur is important in order to prevent them in the future and keep your tail lights in proper working condition.

Identifying Tail Light Wiring Issues

Being able to identify wiring problems is essential for maintaining the safety of your vehicle. Recognizing the signs of tail light wiring issues can help you take prompt action and prevent further damage.

Indicators of wiring problems

There are several indicators that suggest you may have a tail light wiring issue. These include flickering or dim lights, lights that do not turn on at all, or lights that remain on even when the vehicle is turned off. Additionally, a blown fuse or a burning smell near the tail lights can also be signs of wiring problems. If you notice any of these indicators, it is essential to address the issue as soon as possible.

Safety implications of faulty tail light wiring

Faulty tail light wiring can pose serious safety risks. Your tail lights are crucial for indicating your presence on the road to other drivers, especially during low light conditions or when visibility is reduced. Malfunctioning tail lights can make it difficult for other drivers to see your vehicle, increasing the risk of accidents. It is important to address any wiring issues promptly to ensure your safety and the safety of other drivers on the road.

Importance of prompt identification of wiring issues

Prompt identification of tail light wiring issues is vital in order to prevent further damage and ensure proper functioning of your tail lights. Ignoring these issues can lead to more serious problems down the line, including complete failure of the tail lights. By identifying and addressing wiring problems early on, you can avoid potential hazards and save yourself from costly repairs in the future.

Tools Necessary for Dealing with Tail Light Wiring Problems

When it comes to dealing with tail light wiring problems, having the right tools on hand is essential. Here are some tools that will aid you in troubleshooting and resolving wiring issues.

Wire strippers

Wire strippers are essential for removing the insulation from the wires without damaging them. They allow you to expose the copper conductor and make proper electrical connections.

Crimp connectors

Crimp connectors are used to join wires together securely. They provide a strong and reliable electrical connection, preventing loose or weak connections that can lead to further wiring problems.

Electrical tapes

Electrical tapes are used to insulate and protect the wiring connections. They prevent exposed wires from coming into contact with each other or with other metal surfaces, reducing the risk of electrical shorts or sparks.

Multimeter

A multimeter is a versatile tool that allows you to measure electrical voltage, current, and resistance. It is helpful for troubleshooting and diagnosing tail light wiring issues, as it can help you identify faulty wires or connections.

Having these tools readily available will make it easier for you to tackle tail light wiring problems and ensure a smooth and effective repair process.

Using a Wiring Diagram

Understanding how to read a wiring diagram can greatly assist you in troubleshooting tail light wiring issues. A wiring diagram is a visual representation of the electrical connections and components within a system, in this case, the tail light wiring system.

How to read a wiring diagram

Reading a wiring diagram may seem complex at first, but it becomes easier with practice. The diagram consists of lines representing the wires, symbols representing the components, and labels indicating the electrical connections. By familiarizing yourself with the symbols and understanding the flow of the wiring system, you can easily interpret the diagram and locate the tail light wiring.

Locating tail light wiring on a diagram

Once you have a wiring diagram at your disposal, locating the tail light wiring becomes much simpler. Look for the section of the diagram that corresponds to the tail light circuit. This section will show the connections, colors, and paths of the wires specifically related to the tail lights.

Using diagrams for troubleshooting wiring issues

Wiring diagrams are invaluable tools for troubleshooting tail light wiring issues. They allow you to trace the flow of electricity, identify potential problem areas, and verify the correct connections. By utilizing the information provided in the diagram, you can effectively diagnose and resolve any wiring problems you may encounter.

Inspecting the Tail Light Wiring

Inspecting the tail light wiring is an essential step in diagnosing and resolving any issues. A thorough inspection can help you identify faults, loose connections, or damaged wires that may be affecting the performance of your tail lights.

What to look for during inspection

When inspecting the tail light wiring, pay close attention to any visible signs of damage or wear. Look for frayed or broken wires, loose connectors, or signs of corrosion. Additionally, check the routing of the wires to ensure they are not being pinched or compressed by any other components.

How to do a comprehensive check

To perform a comprehensive check, start by disconnecting the tail light assembly from the vehicle. Carefully inspect the wires and connectors for any damage or loose connections. Check the insulation of the wires for any exposed copper or signs of wear. Reconnect the tail light assembly and test the lights to ensure they are functioning properly.

Dealing with detected faults

If you detect any faults during the inspection, take appropriate action to resolve them. This may involve repairing or replacing damaged wires, tightening loose connectors, or cleaning corrosion from the contacts. By addressing the faults promptly, you can restore the functionality of your tail lights and prevent further issues from occurring.

Fixing Loose Connections

Loose connections are a common problem in tail light wiring and can lead to intermittent or non-functional lights. Here is a step-by-step guide on how to locate and fix loose connections effectively.

How to locate loose connections

To locate loose connections, start by inspecting the tail light assembly and wiring. Gently tug on the wires and connectors to check for any movement or play. Pay attention to any loose or wobbly connections that could be causing the issue.

Steps to fix them

Once you have identified a loose connection, the first step is to disconnect the affected connector. Using wire strippers, strip the insulation from the wire slightly to expose fresh copper. Slide the connector over the exposed wire and use crimping pliers to secure it tightly. This will ensure a firm connection and prevent any further movement.

Ensuring a good and sturdy connection

After fixing the loose connection, it is important to ensure a good and sturdy connection. Give the wires a gentle tug to make sure they are securely fastened. Additionally, apply electrical tape to the connectors to provide extra insulation and protection. Double-check the functionality of the tail lights to confirm that the loose connection has been successfully resolved.

Replacing Damaged Wires

If you encounter damaged wires during your inspection, it is crucial to replace them to ensure the proper functioning of your tail lights.

Identifying which wires need replacing

To identify which wires need replacing, carefully examine the extent of the damage. Look for any cuts, tears, or exposed copper. If a wire appears significantly damaged or compromised, it is best to replace it to avoid any further issues.

How to safely remove damaged wires

To safely remove damaged wires, start by making note of the wire’s position and connection points. Using wire strippers, cut the damaged wire at both ends, ensuring a clean and straight cut. Remove the damaged wire from the connectors or terminals, being cautious not to damage any surrounding components.

Correctly installing new wires

When installing new wires, match the color and gauge of the original wire to maintain compatibility. Strip the insulation from both ends of the new wire using wire strippers. Connect one end to the existing wire or terminal and secure it tightly using crimp connectors. Repeat the process on the other end, ensuring that the new wire is securely attached. Finally, insulate the connections with electrical tape to protect them from exposure.

Checking and Changing Fuses and Bulbs

Fuses and bulbs are critical components of the tail light system. Checking them regularly and replacing them when necessary is essential for maintaining the functionality of your tail lights.

How to locate the correct fuse

Locating the correct fuse for your tail lights can vary depending on the vehicle make and model. Start by consulting your vehicle’s owner’s manual, which will provide a fuse box diagram and the corresponding fuse for the tail lights. If the manual is not available, you can also search for the fuse box under the dashboard or in the engine compartment.

Checking if a fuse is blown

To check if a fuse is blown, remove the corresponding fuse from the fuse box. Look for any breaks or discoloration in the filament inside the fuse. If you see any signs of damage, the fuse is likely blown and needs to be replaced.

Replacing bulbs safely

If the tail lights are not functioning properly, it is important to check the bulbs. To replace a bulb, access the tail light assembly and locate the appropriate bulb socket. Twist the bulb socket counterclockwise to remove it, then remove the old bulb from the socket. Insert the new bulb into the socket, making sure it is securely seated. Reinstall the bulb socket into the tail light assembly and test the lights to ensure they are working correctly.

Preventing Future Tail Light Wiring Problems

Taking proactive measures to prevent future tail light wiring problems can save you time, money, and potential safety hazards. Here are some steps you can take to keep your tail light wiring in good condition.

Routine checks and maintenance

Regularly inspect the tail light wiring, connectors, and bulbs to ensure there are no signs of damage or wear. Clean any corrosion from the connectors and apply dielectric grease to prevent future corrosion. Additionally, perform routine checks of the fuses to ensure they are in good working condition.

Being aware of common tail light wiring issues

Educate yourself about common tail light wiring issues and their causes. Understanding the potential problems will enable you to take preventive measures and catch issues before they escalate. Stay informed about any recalls or technical service bulletins related to your specific vehicle make and model.

Prolonging the lifespan of tail light wires

To prolong the lifespan of your tail light wires, avoid excessive strain or tension on the wiring during installation or repairs. Use proper wire routing techniques to minimize rubbing or chafing against other components. Additionally, protect the wires from exposure to moisture and corrosive substances, as these can accelerate damage to the wiring.

Consulting a Professional

While many tail light wiring issues can be addressed by DIY enthusiasts, there may be instances where it is best to consult a professional mechanic.

When to consult a professional

If you are unsure about your ability to diagnose or repair the tail light wiring issue, it is advisable to seek the assistance of a professional. Similarly, if the wiring problem seems complex or if multiple components need to be replaced, a professional mechanic can provide expert guidance.

Finding a trusted mechanic

When choosing a mechanic, it is important to find one with experience in electrical systems and wiring. Ask for recommendations from friends or family, or consult online reviews to find a trusted professional in your area. Ensure that the mechanic is qualified, licensed, and has a good reputation for providing reliable and trustworthy service.

What to expect during a professional inspection

During a professional inspection, the mechanic will evaluate the tail light wiring system, checking for any faults, loose connections, or damaged components. They will use their expertise and specialized equipment to diagnose the issue accurately. Based on their findings, they will provide recommendations for repair or replacement, along with an estimate of the cost and duration of the repairs.

By following these guidelines and being proactive in the care of your tail light wiring, you can ensure a safe and reliable lighting system for your vehicle. Regular inspections, prompt identification and resolution of issues, and appropriate maintenance will help keep your tail lights functioning optimally, providing peace of mind on the road.